Steam Compression Heat Pump

Why a Steam Compression Heat Pump?

Process heat is currently generated by gas-fired installations that use fossil fuels. This is not sustainable and must change. Steam-generating heat pumps offer the solution for decarbonizing the heat supply in various sectors.

- Social focus on sustainability, circularity and electrification

The use of the Steam Compression Heat Pump in the industry

A huge amount of waste heat is produced and get lost by industrial processes. Waste heat is difficult to use. However, effective recovery and utilization of residual heat at a low temperature is possible. Steam is the most important heat carrier in the low and medium temperature range. This means that steam-generating heat pumps can be widely used in various industrial processes. The Steam Compression Heat Pump is a sustainable solution for upgrading residual heat and its use.

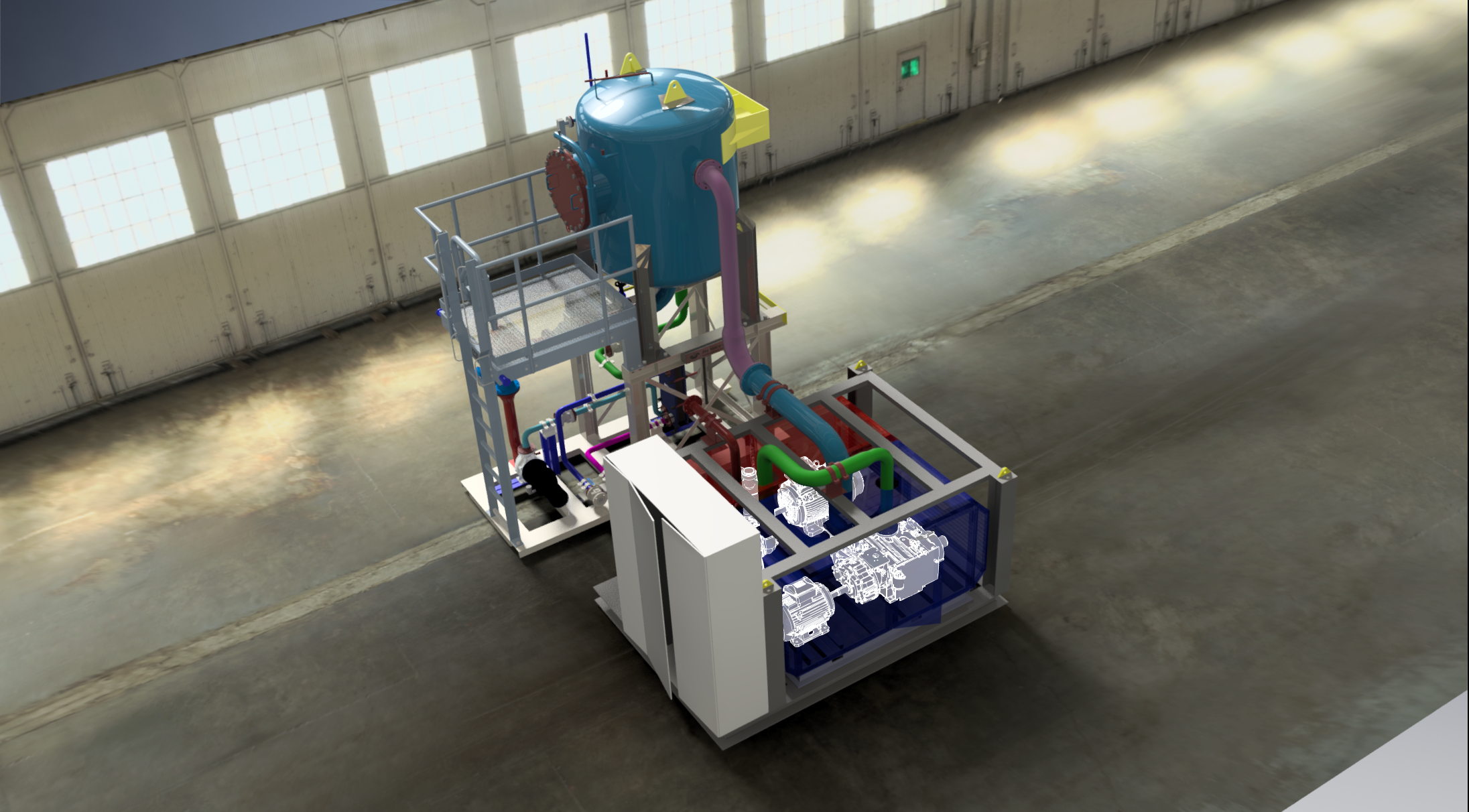

How does the Steam Compression Heat Pump work?

A heat flow, consisting of waste heat, flows through the heat exchanger. Part of the residual heat is extracted and fed into the waste heat boiler. The waste heat boiler contains boiler feed water that is used to make steam. Negative pressure is created to ensure that the low-temperature water evaporates. The vacuum steam discharge is equal to the boiler feed water supply. This is a continuous process. At the same time, the contents of the boiler are drained to maintain the water quality in the boiler at the desired level. In the compressor, the vacuum steam is a higher pressure and a higher temperature. In the condenser the steam condenses to a lower temperature. In the production process, useable steam is used in the energy user’s process. Some of the steam may return as condensate.

Prestation of the Steam Compression Heat Pump

The performance of the Steam Compression Heat Pump is defined as the coefficient of performance. This is the ratio between the process heat and the electric power. A Cop of 1 means that the process heat is equal to the electrical power. The use of waste heat changes the ratio between process heat and electric power, because less electric power is required. The higher the COP, the better the performance and the better the application of the heat pump. Validated test results show a very interesting COP of 3 for the industry at temperatures from 60

℃ and 80℃ to 140℃ and 150℃. This makes the Steam Compression Heat Pump a good choice for the industry.

Pro’s Steam Compression Heat Pump

- CO2-free industrial heating system

- Low operating costs

- Can be used flexibly at different waste heat and process temperatures

- Fits well when using medium pressure steam in the industry