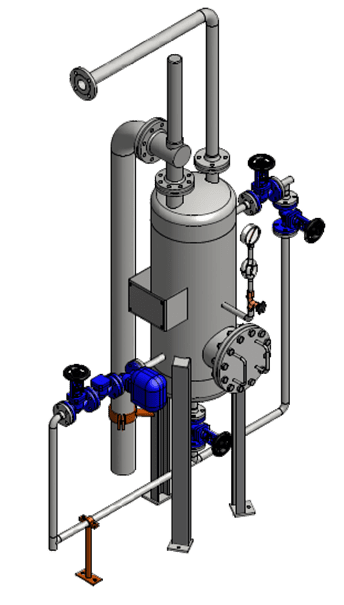

A steam boiler evaporates water by boiling it. The boiler feed water contains solids in suspension to a greater or lesser extent, which remain behind in the boiler. This leads to an accumulation of materials on boiler surfaces. So blowdown to protect the boiler is required in order to remove the materials before boiler scale forms, which can have potentially disastrous consequences. The quality of the boiler feed water is of primary importance in minimising the blowdown discharge. In addition, the residual heat in the discharge water can be recovered.

This can be achieved in a number of ways. The first method is to use a flash tank to expand the hot discharge water to lower the pressure. This generates low pressure steam. Low-pressure steam can be used as an additional source of energy for the feed water deaerator or in a process elsewhere. A heat exchanger can also be used to warm up a cold water flow. In many cases, this will involve the make-up water for the steam system, however a secondary process is just as feasible. The flash tank and heat exchanger can also be used in combination.

Benefits of blowdown water heat recovery

- Increase your system’s efficiency

- Reduce energy costs

- Reduce CO2 emissions

- Quickly recoup your investment

Energy saving with blowdown water heat recovery

You save energy because residual heat is extracted from the discharge water. So the investment in blowdown water heat recovery quickly pays for itself. In addition, the use of this equipment reduces your emissions of CO2 and other harmful substances.

Increase your system’s efficiency

At Standard Fasel, we ensure that the blowdown water heat recovery equipment is a perfect match for your specific situation to achieve the highest possible efficiency.